A subwoofer has to accelerate MORE to play a lower frequency at the same SPL. Why?

To go down one octave requires 4x the stroke - but it's only half as many cycles. The distance traveled over the same time span is actually MORE, so the acceleration is higher at the lower frequency.

E.g. - 40 Hz moving 1" p-p going to 20 Hz will require 4" p-p to produce the same SPL. Let's say that a over one-second time period at 40Hz the cone has moved 40" - at 20 Hz it has moved 80" in that same time.

----------

And to expand on this subject - additional information by Murilo Alvares (Chief Technical Officer):

----------

And to expand on this subject - additional information by Murilo Alvares (Chief Technical Officer):

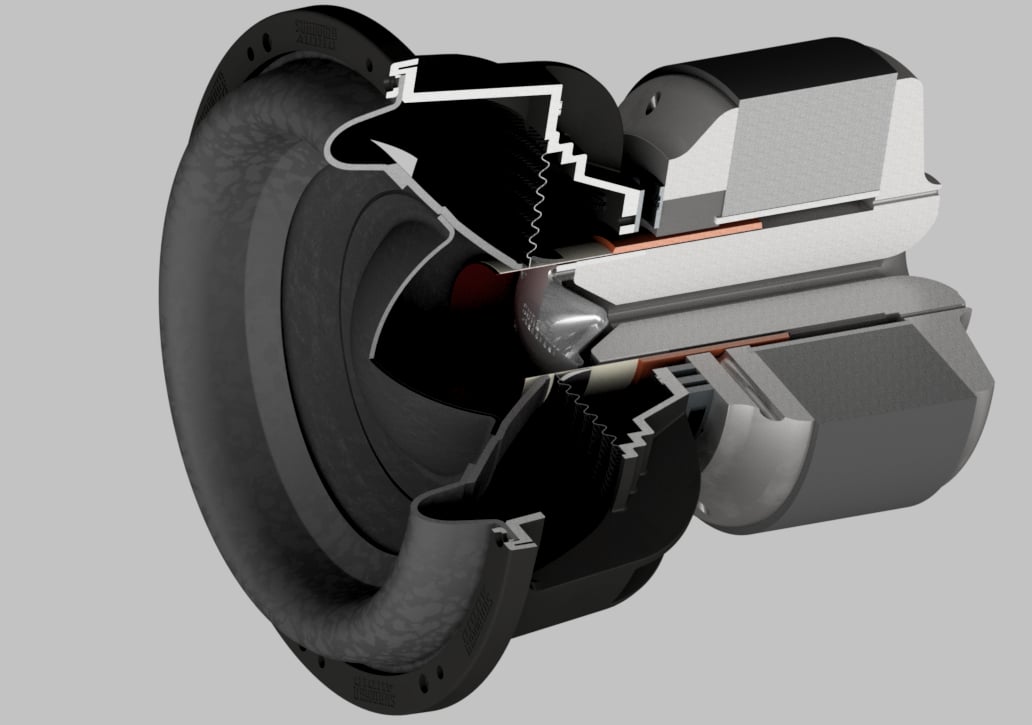

Mechanical considerations on high-performance subwoofers, or why we don’t use generic loudspeaker components.

Back in the 80s, early car audio woofers were basically pro-audio components fitted with more compliant surrounds. Low power amplifiers and high sensitivity loudspeakers were the norm along with large enclosures needed to match with the high acoustic compliance of the speakers (Vas) in order to generate extended low frequency responses, and that lasted until our inherent need to pursue better performance reshaped the way we designed products.

Power! As more powerful (and more affordable) amplifiers became available, we began to see the use of larger voice coils and stiffer suspension elements. Combined with equalization - which is simply a frequency-dependent boost in the voltage sent to the loudspeaker - these changes made it possible to achieve solid low-frequency extension with smaller enclosure volumes.

Multiply all that by 1000 and fast-forward to now: We absolutely crushed it, but not without having to break through some seemingly impossible obstacles. Let’s talk about one: Adhesives. When we have a 5in+ peak-to-peak excursion capable subwoofer like the Sundown Inhuman the stress on key parts of the moving assembly is very high. At peak displacement the suspension must deal with over 5000N, or over 1100 pound-force. A standard triple joint contact area would be subject to over 1.8MPa, or 270PSI, and that would result in a catastrophic failure when the adhesive heats up from the high-power continuous operation. No worries, though - we've engineered specialized triple-joint assemblies into all our high-performance products to ensure everything stays under control.

How fast does it move? Since velocity is the rate of change of displacement, at peak level displacement operation our Zv7 subwoofer cone is moving at 8m/s, or 26 feet per second! Convert this to acceleration – rate of change of velocity – and we get 631.7m/s^2, 64 times the acceleration of gravity!

What if we wanted to sit back, settle for mediocrity and use standard parts from suppliers on our products? Well, the easiest way to do that is by using a weaker motor system. The force a voice coil operating in the magnetic assembly can exert into the suspension is calculated by multiplying the Bl product by the current circulating, so Bl*i. The maximum excursion at very low frequencies will correspond to that force divided by the system stiffness, so by limiting motor force we can ensure that the suspension elements will be subject to reduced stress. It would also allow us to use cheaper, lower shear strength adhesives, but we wouldn’t want to do that, would we? Not when we know that in a vehicle SPL is proportional to the air volume velocity – i.e., cone area x excursion, and that in order to have high cone excursion on reduced volume enclosures we absolutely need strong motor force over a wide excursion range.

3 comments

This seems relevant to what I know about engine building with piston speeds. That said,this analogy is calculating average speed not acceleration rates. As the cone stops and starts, there’s zero acceleration. If it reaches peak speeds by 1/4 of its way back or 3/4 of its way back makes a HUGE difference on peak acceleration without changing average speed.

In an car engine, you can go one step further by changing the rod stroke ratio to slow or raise peak piston acceleration (g forces) without changing the overall piston speeds. Is there an equivalent in the subwoofer world?

Is the inhuman sub available?

Hi, when will the zv7 will be on the market?